|

High temperature epoxy adhesive 9600A/B--Black, high

temperature, such as for automotive ignition of potting |

|

First, the main component

A materials: epoxy resin, filler, additive

B materials: anhydride curing agent, accelerator

Second, product characteristics:

1. Best interoperability

2. Excellent electrical performance

3. Excellent impact resistance properties of hot and cold

4. High heat |

Ignition coil car ignition coil high-tension line

|

Third, the main purpose

Applicable to automotive ignition coil potting

Fourth, packaging specifications

A material: 5kg drum

B materials: 5kg drum

V. Transportation:

This product is non-dangerous goods, according to the general goods

transportation.

Sixth, storage:

1. Confined storage, the best in the next 15 ~ 25 ℃ storage.

2. Avoid direct sunlight.

3. Moisture.

4. Fire.

5. A shelf life of three months is expected, B is expected for 3

months.

Seventh, product characteristics

|

|

Indicators

|

Detection based on |

|

Before curing characteristics |

|

Appearance |

|

Black viscous liquid |

Visual |

|

B |

Yellow viscous liquid |

|

Viscosity

(40℃,mPa

·s) |

A |

15000±5000 |

GB/T2794 |

|

B |

2000±500 |

|

Density

(40℃,g/ml) |

A |

1.75~1.80 |

GB/T4472 |

|

B |

1.30~1.35 |

|

Mixing ratio (weight ratio) |

A:B=100:70 |

/ |

|

Pot life(40℃,h) |

>1 |

/ |

|

Gel time(150℃,min) |

180~250 |

|

|

|

|

Curing material colors |

Black |

|

|

Hardness (25 ℃, D) |

90±5 |

|

|

Flexural strength (25 ℃, N/MM2) |

>80 |

GB/T9341-2000 |

|

Surface resistivity (25 ℃, Ω cm) |

1015 |

GB/T1410 |

|

Volume resistivity (25 ℃, Ω cm) |

1014 |

GB/T1410 |

|

Dielectric constant (25 ℃, 50KHz) |

4.0±0.25 |

GB/T1409 |

|

Dielectric loss (25 ℃, 50KHz) |

0.60 |

|

Water (100 ℃, 1h,%) |

<0.15 |

GB/T1304 |

|

Strength of breakdown voltage (25 ℃, KV / mm) |

>25 |

GB/T1048 |

|

Thermal

conductivity, 25 ℃, W / mK |

>0.7 |

|

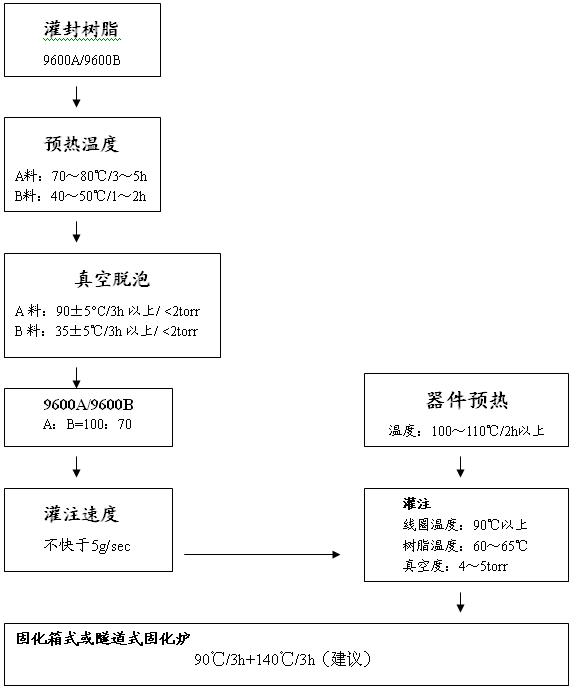

Eighth, potting

process:

IX Notes:

1. Caution

1) The A group contains fillers were easily layered, mixing before use

must be fully uniform, can be 80 ~ 90 ℃ under the conditions of

pre-drying in order to stir 6 ~ 8h.

2) B group of low-temperature storage may have crystal can be 40 ~ 50 ℃

under the conditions of heating to dissolve and then re-use.

3) by the ratio of accurate measurement of A, B groups were not matched

the impact of the prevention of post-curing properties.

2. Operation Notes

1) The workplace should be equipped with ventilation equipment and to

ensure ventilation.

2) the operator should wear protective tool operation, avoid direct

contact with materials.

3) If the material accidentally spilled on the skin, use clean cotton

cloth, etc., or with warm water after the alkali-free soap to wash, skin

irritation or serious burns asked the doctors to help.

4) Any vapor inhalation when feeling unwell immediately carried Office

Outdoor ventilation.

3. Note Storage

1) at low temperature, the shade for storage (preferably 15 ~ 25 ℃).

2) confined to the preservation, in order to avoid entering the water or

other impurities.

3) adhere to FIFO, used in the shelf-life period.

4) open barrel, it should run out as soon as possible to prevent

moisture absorption of impurities into or, if not used after a one-time

residue letters should be good.

|

|

back

|

|